PRE-INSULATED

PIPING SYSTEM

(ABOVEGROUND PIPING SYSTEM, HI-GARD)

General Information

WHERE WHERE

RICWIL preinsulated HI-GARD ™ system is used.SS

- COMMUNITY CENTRAL HEATING AND COOLING

and air conditioning systems for public utilities, municipalities,

housing projects and commercial developments.

- INSTITUTIONS OF ALL TYPES

including universities and colleges, school systems,

hospitals, military establishments installations.

- INDUSTRIAL PLANTS

for pipe line electric heating, industrial processing, air conditioning,

generating electricity, oil storage and handling.

- HIGH RISE BUILDINGS

non-condensation preinsulated piping system for high rise building

in a tropical region.

BENEFITS

- SINGLE SOURCE FOR ENTIRE

SYSTEM

Give Ricwil® one purchase order and

receive a complete preinsulated HI-GARD™ system including

carrier pipe, thermal insulation, protective jacketing, prefabricated

fitting and joining materials to meet customer requirements.

- DESIGN FLEXIBILITY

Ricwil's®

aboveground preinsulated piping systems are not a stock item

but rather a combination of available materials that meet each

customer's specific design requirements. Ricwil's®

approach to aboveground piping offers the designewr more latitude

in his selection of carrier pipe, insulation, protective jacket

and pipe joining method. He has the added benefit of being able

to add tracing, as required. Ricwil's®

aboveground preinsulated piping systems are not a stock item

but rather a combination of available materials that meet each

customer's specific design requirements. Ricwil's®

approach to aboveground piping offers the designewr more latitude

in his selection of carrier pipe, insulation, protective jacket

and pipe joining method. He has the added benefit of being able

to add tracing, as required.

- PREFABRICATED TO ACTUAL JOB REQUIREMENTS

AND DIMENSIONS

A complete system in 6 to 12 meter unitt lengths is delivered

to the job site along with fittings and accessories. Each unit

can be part numbered for easy identification during installation.

Prefabrication reduces material storage and handling requirements

and eliminates waste and damage.

- QUALITY CONTROLLED

All Ricwil® preinsulated HI-GARD™

systems must pass a rigid inspection at our plant - not the

customer's. Modern techniques and well trained fabricators are

the customer's assurance of quality. Ricwil®

preinsulated HI-GARD™ systems arrive at the jobsite with

all insulation protected from elements. Insulation remains dry

and efficient throughout shipping, storage and installation.

- FASTER INSTALLATION

Installation drawings can be supplied detailing all mechanical

components, and electrical if required. No guesswork. Six to

twelve meter of preassembled pipe, insulation and jacketing

is installed at one time leaving only the pipe joint exposed

for testing and field insulating. No longer is it necessary

for an insulator to wait until the pipe fitter is finished to

re-erect scaffolding. Nor is the mess of field applied insulation

there to be cleared up after the insulator is finished.

- REDUCED FIELD COSTS

Ricwil's®

aboveground, preinsulated HI-GARD™ system improves upon

the old way of field applied insulation and jacketing in new

construction and reduces time and disruption to production in

existing facilities requiring renovation, replacement, or additions.

Preinsulated, prefabricated systems containing one or more pipes

simplify and reduce expensive pipe stanchions. Ricwil's®

aboveground, preinsulated HI-GARD™ system improves upon

the old way of field applied insulation and jacketing in new

construction and reduces time and disruption to production in

existing facilities requiring renovation, replacement, or additions.

Preinsulated, prefabricated systems containing one or more pipes

simplify and reduce expensive pipe stanchions.

With all your insulated piping system components purchase at

one time, prefabricated, from one source to meet your particular

design requirements, you achieve the highest product quality

and maximum installation efficiency. Let RICWIL

show you how to obtain the lowest installed cost for your aboveground

HI-GARD™ system.

LO-TEMP HI-GARD

RICWIL'S

Lo-Temp Hi-Gard piping system is the highest quality, most effifient

and dependable method of providing for obove-ground distribution

of fluids at temperatures up to 130°C. RICWIL'S

Lo-Temp Hi-Gard piping system is the highest quality, most effifient

and dependable method of providing for obove-ground distribution

of fluids at temperatures up to 130°C.

Lo-Temp Hi-Gard is prefabricated to improve quality

and save labor, the Lo-Temp Hi-Gard piping system is completely

preinsulated to satisfy insulation and jacketing needs for all above-ground

applications, indoors and outside.

Lo-Temp Hi-Gard provides the unparalleled thermal

efficiency of factory-apllied poly-urethane insulation, protected

by any one of a multitude of jacket materials. Metal jackets of

aluminum, galvanized steel, plasticcoated galvanized steel, stainless

steel, and U.V. inhibited plastic jacket of PVC and polyethylene

are all available. Lo-Temp Hi-Gard components are factory assembled

including all necessary fabricated fitting, such as ells, tees,

expansion loops and anchors, so a complete system ready for fast

installation is delivered to the jobsite. Supporting of the Lo-Temp

Hi-Gard system is simplified by the capability of supporting from

the outside of the protective jacket.

MID-TEMP HI-GARD

RICWIL'S

Mid-Temp Hi-Gard piping systemprovides superior BTU saving in addition

to an efficient, high quality, labor-saving method of providing

for the distribution of fluids above-ground at temperatures of 130°C

and above. RICWIL'S

Mid-Temp Hi-Gard piping systemprovides superior BTU saving in addition

to an efficient, high quality, labor-saving method of providing

for the distribution of fluids above-ground at temperatures of 130°C

and above.

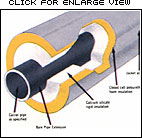

A combination of calcium silicate and polyurethane

insulation makes BTU savings possible. These savings are extremely

desirable in electric-traced applications where every BTU saved

lowers electrical equipment material cost and adds to lifelong savings

in power usage. These savings also justify Mid-Temp Hi-Gard purchase

for many district cooling and heating applications, where every

BTU delivered to a customer brings added income to the system owner.

Supporting of pipe system is simplified by capability of supporting

from the outside of the protective capability of supporting from

the outsideof the protective jacket.

Completely prefabricated and preinsulated, the

Mid-Temp Hi-Gard piping system meets the design requirements of

all above-ground installations for services of and above where maximum

BTU savings are desired. Mid-Temp Hi-Gard maintains thermal efficiency

indoors and outside. It consist of a highly thermal-efficient inner

layer of calcium silicate, an outer layer of polyurethane factory-applied

to the rrequired thickness and density, and a protective jacket

of a material best suited to the application. Metal jackets of aluminum,

galvanized steel, plastic coated galvanized steel, stainless steel,

and U.V. inhibited plastic jackets of PVC and polyethylene are all

avialable. These components are efficiently factory assembled, including

all necessary fabricated items such as ells, tees, expansion loops,

anchors, etc., to deliver a complete system to the jobsite.

HI-TEMP HI-GARD

RICWIL'S

Hi-Temp Hi-Gard piping system provides maximum durability in addition

to an efficient, high quality, labor saving method of providing

for the distribution of fluids above ground at temperatures above

150°C. RICWIL'S

Hi-Temp Hi-Gard piping system provides maximum durability in addition

to an efficient, high quality, labor saving method of providing

for the distribution of fluids above ground at temperatures above

150°C.

The combination of RICWILs exclusive nonflammable

insulation locking agent with calcium silicate makes maximum system

economy possible.

Hi-Temp Hi-Gard is a specially formulated, high-strength

inorganic locking agent that exhibits virtually no temperature limitations

when used in a RICWIL piping system.

The inorganic locking agent's high-compression

strength, plus the combination of insulation materials that allows

RICWIL to apply the minimum thickness of insulation required to

maintain desired temperatures, results in a rugged, durable system.

A system that allows maximum bearing loads with maximum support

spans. These design savings are added to the economy of Hi-Temp

Hi-Gard minimum insulation thickness.

Completely preinsulated to handle all temperatures,

the prefabricated piping system is particularly suited for indoor

and outside applications. Supporting the Hi-Temp Hi-Gard system

is simplified by capability of supporting from the outside of the

protective jacket.

Hi-Temp Hi-Gard consists of inner layer of calcium

silicate insulation, factory applied to the required thickness,

sealed with a polyethylene shield, covered by an outer layer of

RICWILs exclusive inorganic locking agent for strength, and protected

by any one of a multitude of metal jacket materials.

Hi-Temp Hi-Gard's nonflammable barrier permits

its use in all commercial and industrial environments.

Metal jackets of spirally locked seam aluminum,

galvanized steel. Plasticcoated galvanized steel and stainless steel

are available. These components are factory-assembled including

all necessary fittings, such as eils, tees, expansion loops, and

anchors, so a complete system ready for fast installation is delivered

to your job site.

Engineering Data

INSULATION

The insulation shall be a rigid polyurethane foam and completely

fill the annular space between carrier pipe and outer jacket.

- PHYSICAL PROPERTIES OF RIGID POLYURETHANE FOAM

| PHYSICAL PROPERSIES |

METRIC |

METRIC |

METRIC |

ASTM

TEST |

DENSITY

|

45

kg/m³ |

50

kg/m³ |

75kg/m³ |

D1622 |

| THERMAL CONDUCTIVITY |

0.017Kcal/m.h.°C

(0.02W/m.°K) |

0.018Kcal/m.h.°C

(0.021W/m.°K) |

0.020Kcal/m.h.°C

(0.023W/m.°K) |

C518 |

| COMPRESSIVE STRENGTH |

2.0kgf/cm² |

2.8kgf/cm² |

5.0kgf/cm² |

D1621 |

| CLOSED CELL CONTENT |

90% |

91% |

97% |

D2856 |

| WATER VAPOUR PERMEABILITY |

3.7PERM-CM

(2.2PERM-IN) |

3.5PERM-CM

(2.1PERM-IN) |

2.5PERM-CM

(1.5PERM-IN) |

C355 |

|

Above density is RICWIL's standard and varies as fluid temperature

increases. Higher density polyurethane foam is available upon

request.

- K-Factor (comparative) @ 20°C

mean temperature

| RIGID POLYURETHANE

FOAM |

ROCKWOOL |

FIBERGLASS |

CALCIUM SILICATE |

| 0.017Kcal/m.h.°C |

0.034Kcal/m.h.°C |

0.030Kcal/m.h.°C |

0.048Kcal/m.h.°C |

|

Download Section

The specifications have been formatted to be viewed with Adobe®

Acrobat® Reader software. If you don't have an Acrobat®

Reader, please

download it here. |

ENGINEERING DATA

INSTALLATION DATA

GUIDE SPECIFICATION

PRODUCT SKETCHES AND PIPE SUPPORT

|